Why Type Approval matters for Maritime Electronics

March 5, 2025

Table of contents

Type approval in the maritime industry serves as a stamp of reliability, ensuring that electronic equipment meets strict safety and performance standards. This certification demonstrates a product’s ability to withstand the harsh conditions at sea. For manufacturers and vendors, obtaining type approval is more than a regulatory formality—it is a strategic step that fosters market acceptance, reduces risks, and extends the product’s lifespan.

What Is Type Approval?

Type approval acts as a universal standard, ensuring that marine electronic products meet industry-wide requirements. A product, system, or vessel only receives this certification after undergoing rigorous testing and verification against criteria set by a recognized classification society.

For marine electronics, type approval isn’t just a bureaucratic step. It’s an essential part of product development, ensuring that hardware and systems can withstand the relentless marine environment with extreme temperatures, high humidity, continuous vibration, and electromagnetic interference. Simply put, type approval separates trustworthy equipment from the rest.

Regulatory Framework

Several organizations define and enforce type approval requirements:

- International Maritime Organization (IMO) – Sets global safety and operational standards.

- International Electrotechnical Commission (IEC) – Develops technical benchmarks for marine electronics.

- Classification Societies – Groups like Lloyd’s Register (LR), American Bureau of Shipping (ABS), Bureau Veritas (BV), and DNV conduct compliance evaluations.

- Marine Equipment Directive (MED) – Regulates safety compliance for EU-flagged vessels, granting the “Wheel Mark” certification to compliant products.

How to Attain Type Approval

Some manufacturers integrate type approval testing directly into their product development cycle, ensuring their equipment is market-ready upon launch. Others take a riskier, cost-cutting approach—opting for non-approved hardware and leaving certification to the system integrator. While this may seem more affordable initially, the hidden costs can quickly accumulate. Without type approval, there’s no guarantee that a product will meet regulatory standards, meaning manufacturers might face expensive delays, rework, or even rejection in the final approval stages.

The Type Approval Process

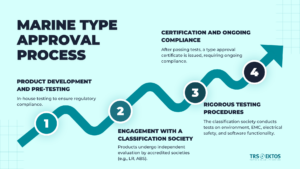

The road to type approval involves several key steps:

- Product Development and Pre-Testing

- Manufacturers conduct in-house testing to ensure compliance with regulatory standards.

- Engagement with a Classification Society

- Products are submitted to an accredited classification society (e.g., LR, ABS) for independent evaluation.

- Rigorous Testing Procedures

- The classification society carries out extensive tests, including:

- Environmental Stress Tests (temperature cycles, salt mist exposure, vibration resistance)

- Electromagnetic Compatibility (EMC) Tests (radiated emissions, interference immunity)

- Electrical Safety Checks (power supply variation, insulation resistance, fault protection)

- Software and Functional Assessments (failover mechanisms, cybersecurity resilience)

- The classification society carries out extensive tests, including:

- Certification and Ongoing Compliance

- Once all tests are passed, the classification society issues a type approval certificate. Manufacturers must maintain compliance through periodic testing and updates.

Benefits of Type Approval

Opting for type-approved marine electronics offers several advantages:

- Market Acceptance – Type-approved products gain immediate credibility and preference among shipbuilders and fleet operators.

- Risk Mitigation – Certified products reduce liability concerns, ensuring compliance with legal and insurance requirements.

- Operational Reliability – Type-approved equipment is built to withstand the toughest maritime conditions, minimizing failures and costly downtime.

Mutual Recognition of Type Approval

The European Union has established a mutual recognition framework for type approval certificates, allowing EU-recognized classification societies to accept each other’s certifications. This simplifies market entry by ensuring that a product certified by one recognized organization is generally accepted by others while maintaining consistent safety standards.

Conclusion

For marine electronics manufacturers entering the European market or the global shipping industry, type approval is more than a regulatory step; it’s a mark of quality and reliability. Skipping certification might seem like a shortcut, but the risks can lead to costly delays and lost opportunities. Choosing type-approved hardware from the start builds trust with shipowners, ensures a smoother market entry, and strengthens long-term success in the maritime sector.