How ISO 13485 Drives Compliance and Quality in Medical Electronics Manufacturing

December 4, 2024

Table of contents

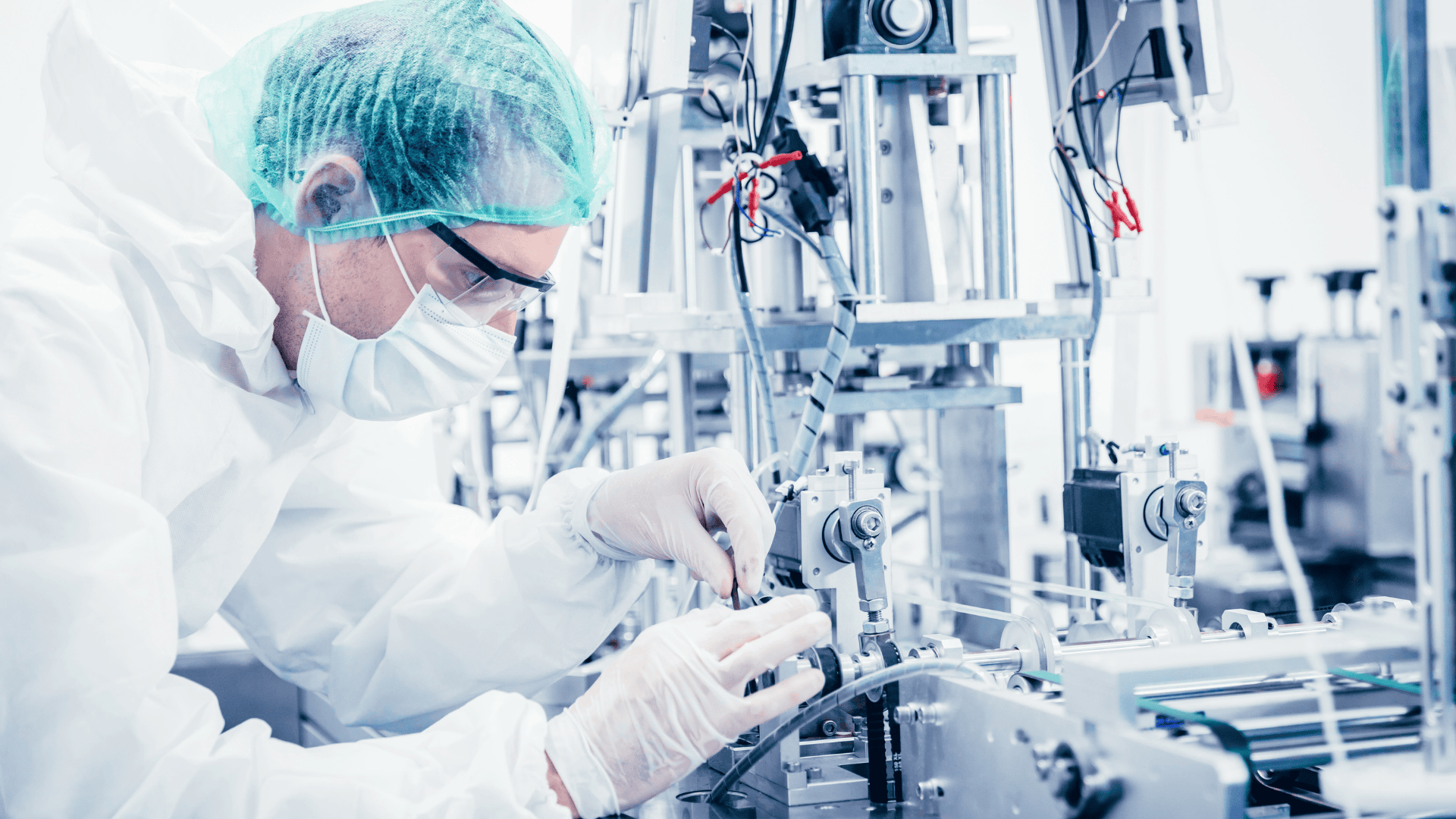

The medical electronics industry is highly regulated. Ensuring your products meet strict safety and quality standards can be challenging. Without proper guidelines, such as those offered by ISO 13485, medical electronics manufacturers risk costly delays, non-compliance, and potential safety issues that could damage their reputation and customer trust.

Adhering to the standard goes beyond meeting regulatory requirements. It drives innovation and ensures reliable, high-performing medical electronics that have been manufactured with robust quality practices at every stage of the production process.

In this article, we will cover how implementing ISO 13485 can help you stay competitive minimize risks, and build customer confidence with the way it shapes your compliance framework.

What Is ISO 13485?

ISO 13485 is an internationally recognized standard for the quality management systems (QMS) of organizations involved in the design, production, installation, and servicing of medical devices. Unlike general QMS standards such as ISO 9001, ISO 13485 is specifically tailored to meet the rigorous regulatory requirements of the medical device industry. This standard ensures that the entire lifecycle of a product, from initial development to post-market surveillance, adheres to strict quality and safety protocols.

Key features of ISO 13485 include:

- A strong focus on risk management and design controls.

- Emphasis on traceability throughout the supply chain.

- Compliance with regulatory and customer-specific requirements for medical electronics.

Electronics manufacturers aiming to supply to the healthcare sector must adopt this standard to remain competitive and credible.

Why Is ISO 13485 Crucial for Electronics Manufacturing?

The increasing complexity of medical electronics and the rapid pace of technological advancements necessitate a robust framework to maintain safety and functionality. Adopting ISO 13485 helps manufacturers ensure their products are:

- Compliant with global regulations: Meeting the diverse requirements of markets such as the EU, the US, and Asia.

- Reliable and safe: Mitigating risks associated with device failure or malfunction, which could have life-threatening consequences.

- Market-ready: Easing regulatory approval processes, reducing time-to-market, and improving credibility.

For electronics manufacturers working on products such as implantable devices, diagnostic equipment, or patient monitoring systems, adhering to ISO 13485 is no longer optional—it’s essential.

Key Components of ISO 13485 in Electronics Manufacturing

1. Design and Development Controls

In electronics manufacturing, the design and development phase lays the foundation for a product’s performance. ISO 13485 requires you to document and validate the design and development process. This includes:

- Conducting thorough risk assessments to identify potential hazards early.

- Maintaining a design history file (DHF) to ensure transparency in design iterations.

- Implementing robust verification and validation processes to confirm the product meets its intended use.

These controls ensure that manufacturers can meet stringent regulatory requirements and deliver products that perform flawlessly in real-world applications.

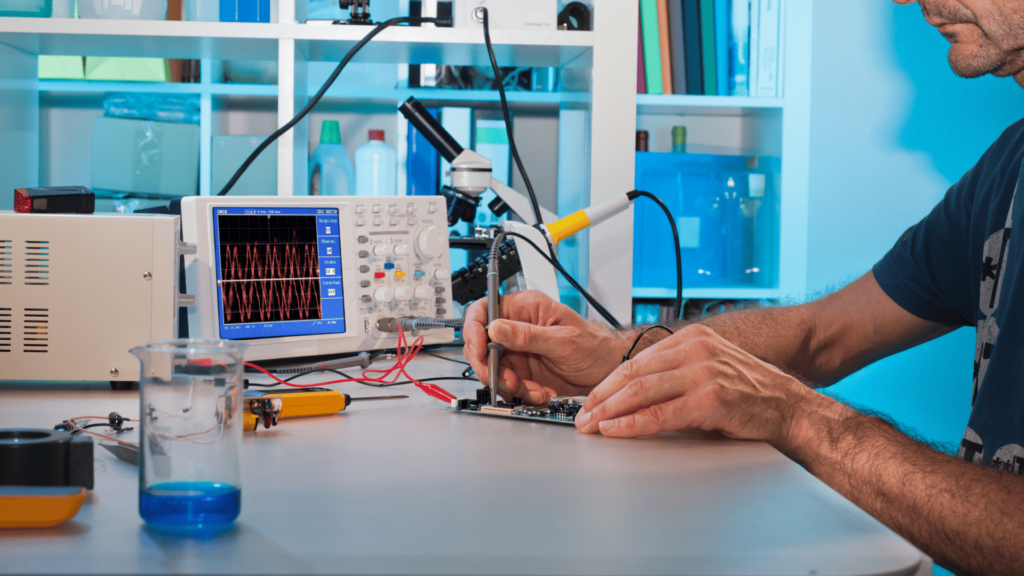

2. Risk Management

ISO 13485 integrates risk management throughout the product lifecycle, aligning with ISO 14971 for medical device risk. For electronics manufacturers, this involves:

- Evaluating risks related to hardware and software failures.

- Mitigating risks associated with electromagnetic interference (EMI).

- Meeting electromagnetic compatibility (EMC) standards.

Effective risk management not only enhances product reliability but also strengthens customer trust and regulatory approval.

3. Traceability and Documentation

In the medical device industry, traceability is a non-negotiable requirement. ISO 13485 ensures that every component of an electronic device can be traced back to its source, allowing for efficient recalls or investigations if necessary.

Electronics manufacturers must maintain:

- Detailed batch records for all components and assemblies.

- Comprehensive supplier management protocols to ensure consistent quality.

- A well-structured device master record (DMR) containing all production details.

Traceability systems are critical for managing compliance and providing evidence of quality assurance during audits.

4. Supplier Quality Management

The reliance on a global supply chain in electronics manufacturing means that ensuring supplier quality is paramount. ISO 13485 mandates that manufacturers:

- Perform regular supplier audits to verify compliance.

- Maintain a list of approved vendors and regularly evaluate their performance.

- Establish clear quality agreements with suppliers to outline expectations.

These measures ensure that the quality of raw materials and components aligns with regulatory and customer requirements.

Benefits of ISO 13485 for Your Product

1. Faster Market Access

With ISO 13485 certification, manufacturers can streamline regulatory approvals, particularly for CE marking in Europe or FDA clearance in the US. This accelerates the time-to-market for in your novative medical electronics.

2. Enhanced Product Credibility

ISO 13485 is widely recognized as a mark of quality. Products developed under this framework are perceived as safer, more reliable, and compliant with global standards, enhancing their appeal to customers and stakeholders.

3. Reduced Risk of Non-Compliance

Failure to meet regulatory requirements can lead to costly delays, fines, or product recalls. ISO 13485 minimizes these risks by ensuring that every stage of production meets stringent quality and safety standards.

4. Competitive Advantage

ISO 13485 certification shows commitment to high standards, making your products more appealing and building customer trust, which gives you an edge over competitors.

Implementing ISO 13485 in Electronics Manufacturing

Adopting ISO 13485 requires a commitment to quality at every level of the organization. The implementation process involves:

- Conducting a gap analysis to identify areas that need improvement.

- Developing and documenting a robust QMS tailored to ISO 13485 requirements.

- Training employees on quality standards and best practices.

- Partnering with a reliable certification body to conduct audits and issue the certification.

For medical electronics manufacturers, the journey to ISO 13485 certification is an investment in quality, safety, and customer satisfaction.

The Role of ISO 13485 in Driving Innovation

ISO 13485 doesn’t restrict innovation; it supports it with a structured framework. By addressing compliance and quality concerns upfront, manufacturers can focus on developing groundbreaking products that improve patient outcomes. From wearable health monitors to AI-driven diagnostic tools, the potential for innovation in medical electronics is vast, and ISO 13485 serves as the foundation for success.

Ready to get started? TECHTO Electronics can be your trusted manufacturing partner for bringing your new or existing medical products to market with precision and compliance. Contact the TECHTO team today.