Electronics Design Reviews: 10 Essential Steps for Project Success

November 26, 2024

Table of contents

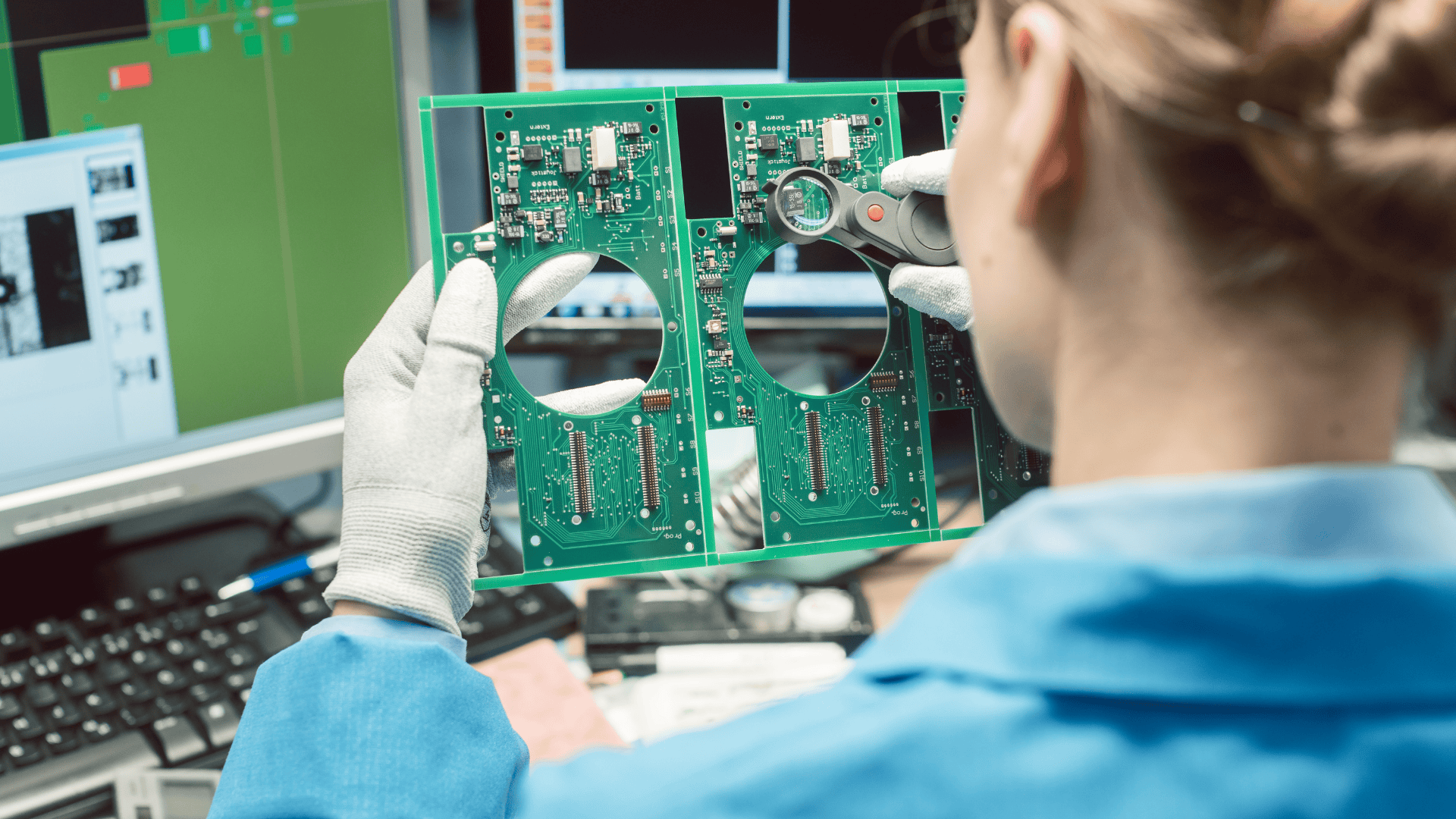

What if a single missed detail could compromise your product’s quality and reliability?

This is why electronics design reviews are crucial— they catch issues early, prevent costly mistakes, and ensure success before launch. By identifying potential problems and addressing them promptly, design reviews lead to better outcomes and a smoother development process.

In this guide, we’ll outline essential steps for conducting electronics design reviews that result in reliable, high-performing products.

Why Electronics Design Reviews Are Essential

Design reviews are more than just checkpoints; they are an integral part of the electronics design lifecycle. They serve as a guide to uncover problems, validate requirements, and streamline team efforts. Additionally, these reviews help document decisions, align expectations, and set the stage for future improvements.

Steps for Conducting an Effective Electronics Design Review

Without further ado, here are ten essential steps for a successful electronics design review:

1. Define Clear Objectives for the Design Review

Before diving into a design review, it’s essential to establish the specific goals you want to achieve. These objectives should reflect the project’s requirements, focusing on aspects like functionality, compliance, cost considerations, and performance reliability.

Key Objectives to Consider:

- Ensuring functionality meets requirements

- Verifying compliance with industry standards

- Identifying potential reliability issues

- Reviewing design for manufacturability (DFM)

- Reducing risks of design-related delays

2. Assemble a Multidisciplinary Review Team

An effective design review requires input from various perspectives. Ensure your review team includes individuals with diverse expertise, such as electrical engineers, firmware developers, mechanical engineers, and quality assurance specialists. A cross-functional team provides a holistic view of the design and ensures thorough evaluation.

Suggested Team Roles:

- Project Manager: Ensures the review stays focused on objectives and deadlines.

- Lead Engineer: Provides in-depth technical expertise and insights.

- Quality Assurance: Evaluates reliability and compliance aspects.

- Manufacturing Specialist: Offers feedback on manufacturability and cost-effectiveness.

- Firmware/Software Engineer: Assesses firmware integration for embedded systems.

3. Review the Design Documentation Thoroughly

Comprehensive and accurate documentation is fundamental to any design review process. Ensure all relevant materials, such as schematics, PCB layouts, bills of materials (BOMs), and firmware documentation, are current and accessible to the team. This enables accurate assessments and prevents misunderstandings.

Documentation Checklist:

- Schematics: Verify electrical connections, component values, and design configurations.

- PCB Layout: Check for proper trace routing, component placement, and layer usage.

- Bill of Materials (BOM): Confirm components’ availability, lead time, and cost.

- Firmware Documentation: Check for seamless hardware-software compatibility.

- Compliance Documents: Validate alignment with regulatory and safety standards.

4. Focus on Critical Design Aspects

While every part of the design deserves attention, certain aspects are more likely to have a higher risk of causing delays or performance issues. Focusing on these areas helps the team detect potential problems early before they escalate.

Areas to Focus On:

- Power Supply: Check for stability, efficiency, and potential noise issues.

- Thermal Management: Ensure safe operation across temperature ranges.

- Signal Integrity: Confirm that the PCB layout minimizes noise and signal degradation.

- Component Placement and Footprints: Validate spacing and alignment for manufacturability.

- Mechanical Fit and Form: Ensure components are compatible with housing requirements.

5. Use Design Review Checklists for Consistency

Standardized checklists ensure a systematic approach to the review process, reducing the likelihood of overlooking critical elements. Tailor these checklists to align with your project’s needs.

Sample Checklist Items:

- Are all components rated for the operating voltage and current?

- Has thermal management been accounted for?

- Are key signal pathways optimized for performance?

- Has the layout been optimized for manufacturability?

- Are all required compliance standards met?

6. Identify Potential Risks and Mitigation Strategies

During the review, it’s essential to identify potential risks that could impact product performance, reliability, or time to market. These risks may relate to component availability, design complexity, regulatory compliance, or manufacturing challenges. Addressing these risks early through thoughtful planning can save time and resources.

Common Risks and Mitigation Examples:

- Component Obsolescence: Choose widely available components and consider secondary suppliers.

- Thermal Overload: Implement heatsinks, and thermal pads, or consider redesigning the layout.

- Firmware Integration Issues: Schedule early firmware-hardware integration testing during earlier phases.

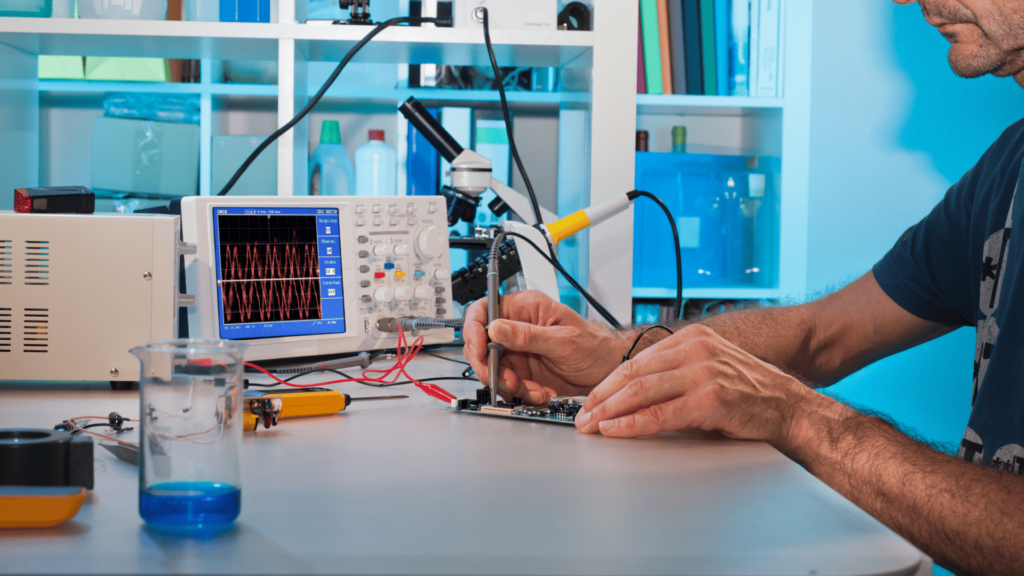

7. Conduct Design-for-Manufacturability (DFM) and Design-for-Test (DFT) Checks

Avoid costly delays and ensure efficient production, by assessing the design for manufacturability (DFM) and testability (DFT). This step helps identify design elements that may be challenging to assemble, manufacture, or test. Addressing these aspects early in the design review process saves time, reduces costs, and ensures smoother production.

DFM and DFT Considerations:

- Component Accessibility: Ensure critical components are accessible for testing or repairs.

- Assembly Complexity: Minimize complex assembly steps that could lead to production delays.

- Test Points: Include adequate test locations for post-production verification.

8. Incorporate Collaboration Tools

Design reviews are most effective when all team members can efficiently contribute their insights. To ensure a cohesive evaluation process, use software for schematic visualization, PCB layout review, and real-time commenting.

Benefits of Collaboration Tools:

- Faster feedback cycles.

- Centralized record of comments and updates.

- Clear communication across all team members.

9. Schedule Multiple Review Stages for Complex Projects

Large or intricate projects often benefit from breaking the review process into manageable stages. Stages, such as preliminary, intermediate, and final reviews, allow the team to address issues progressively and avoid overlooking critical aspects due to time constraints.

Stages to Consider:

- Preliminary Review: Assess design concepts and basic requirements.

- Intermediate Review: Examine schematics, layouts, and early prototypes.

- Final Review: Conduct a detailed evaluation before production begins.

10. Document Findings and Plan Follow-Up

After completing the design review, document all findings, decisions, and action items. Clear documentation ensures clarity and accountability. Before progressing to the next stage, consider scheduling a follow-up meeting to confirm all issues have been addressed.

Key Documentation Elements:

- Summary of Issues: List identified issues and their priority levels.

- Action Items: Assign specific tasks to team members for resolution.

- Approval Records: Document sign-offs from all key disciplines.

Conclusion

Thorough design reviews are essential for minimizing errors, avoiding delays, and producing high-quality electronic products. By setting clear goals, assembling a multidisciplinary team, focusing on critical elements, and using collaborative tools, your team can conduct efficient reviews that contribute to the success of your project.