Choosing the right BLDC motor for your project

September 24, 2024

Table of contents

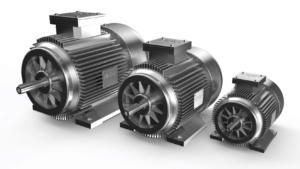

When choosing the right BLDC (Brushless DC) motor for your project, it’s not just about finding a motor that works—it’s about selecting one that will deliver maximum efficiency, reliability, and performance in your specific application.

Whether you’re building an electric bike, a robotic arm, or a climate control system, the motor you choose plays a pivotal role in ensuring smooth operation. But where do you start?

In this guide, we’ll explore key factors to consider, from motor specifications to control interfaces, environmental demands, and cost considerations, helping you make an informed decision for your next project.

Understanding BLDC Motor Specifications

Selecting the ideal BLDC motor begins with understanding its core specifications. A BLDC motor is known for its efficiency and durability, but how do you assess which one is right for you?

Here are the critical parameters to evaluate:

- Voltage Rating: This defines the operational voltage range of the motor. Ensure it matches your power supply to avoid performance issues.

- Current Rating: This tells you how much current the motor can handle before overheating. It’s important to match this with your system’s needs to prevent overloading.

- Speed (RPM): RPM, or Revolutions Per Minute, indicates how fast the motor spins under load. If you need high-speed applications, this is a key metric.

- Torque Rating (Nm): Torque measures the motor’s rotational force. High torque is essential for applications requiring significant load handling.

- Efficiency and Thermal Characteristics: Consider the motor’s energy consumption and ability to dissipate heat. Higher efficiency reduces power usage and lowers heat generation, crucial for long-term operation.

Understanding these specifications allows you to align the motor’s performance with your project’s demands, ensuring both efficiency and longevity.

Application specific considerations

When it comes to the application of Brushless DC (BLDC) motors across various industries, each sector has its specific considerations that must be taken into account to ensure optimal performance and efficiency.

Let’s explore how BLDC motors fit into a range of sectors:

- Aerospace: Reliability and weight are critical. BLDC motors must be lightweight yet robust enough to handle extreme conditions like temperature fluctuations and pressure changes. Efficiency is key to maximizing battery life in electric aircraft applications.

- Automotive: In electric vehicles (EVs) and hybrid systems, thermal management is crucial to prevent overheating. Compatibility with regenerative braking systems and compliance with safety standards are also important considerations.

- Robotics: Precision and low noise levels are paramount. Advanced feedback systems for real-time adjustments ensure accurate control in movement-intensive applications.

- HVAC Systems: Energy efficiency and quiet operation are essential. The motor must handle continuous duty cycles while adjusting to varying load conditions.

- Electric Bicycles: For e-bikes, weight is a significant factor, directly affecting performance and user experience. The motor should offer enough power without adding excessive weight, ensuring smooth acceleration and reliable battery life.

Each application comes with its own set of demands. Choosing a motor that aligns with the specific challenges of your industry ensures meeting industry demands effectively.

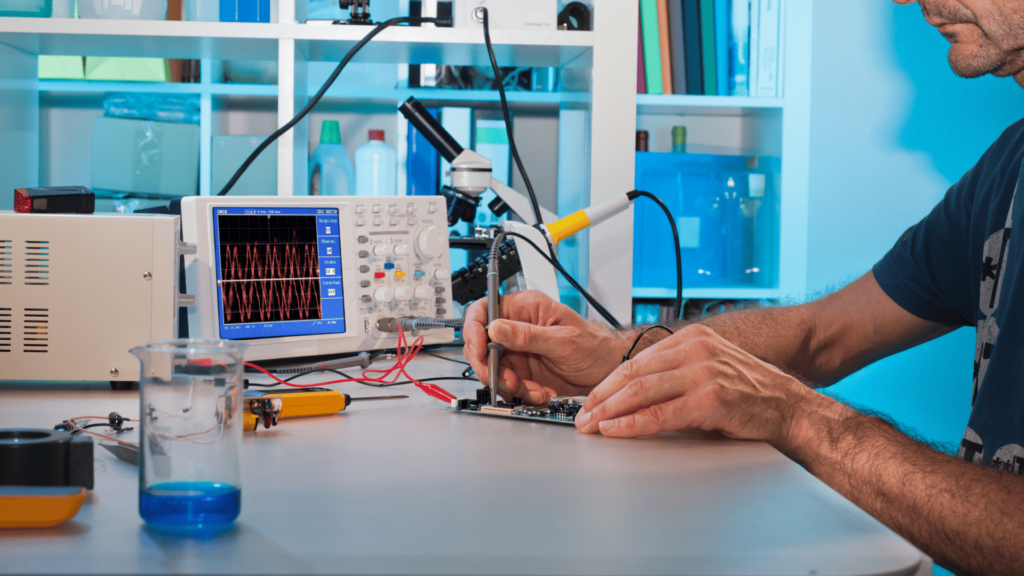

Control and Communication Interface

The control and communication interface of a BLDC motor impacts its overall functionality. Understanding whether to use a sensored or sensorless BLDC motor can make a big difference in your application.

Sensorless BLDC motors rely on back EMF for rotor position detection, making them simpler and often more cost-effective. However, they may struggle with low-speed performance or during startup conditions.

In contrast, sensored BLDC motors utilize feedback from sensors to provide precise control over the motor’s position and speed, resulting in enhanced performance in applications requiring high torque at low speeds.

Additionally, communication protocols play a significant role in the effectiveness of control systems.

- CANbus: Widely used in automotive applications due to its robustness and ability to handle multiple nodes on a single network

- PWM (Pulse Width Modulation): Favored for its simplicity and efficiency in controlling motor speed through varying voltage levels

- UART (Universal Asynchronous Receiver-Transmitter): Common for serial communication due to its simplicity and low cost.

Choosing the right control and communication interface can simplify integration and enhance motor performance in your project.

Environmental factors

Environmental conditions play a significant role in the long-term reliability and performance of your BLDC motor. Here’s what to consider:

Operating Temperature Range

Every piece of equipment has a specified operating temperature range that indicates the conditions under which it can function optimally. Exceeding the recommended temperature range can cause overheating or degradation of performance. Ensure the motor is rated for the specific temperatures it will encounter.

IP Rating for Dust and Water Resistance

The Ingress Protection (IP) rating system provides valuable insights into a device’s resistance to dust and moisture. For example, an IP67 motor is completely dust-tight and can withstand immersion in water for up to 30 minutes.

Vibration and Shock Resistance

Equipment used in dynamic environments must also be evaluated for vibration and shock resistance. Devices with high vibration or shock resistance are designed to endure sudden impacts or continuous vibrations without sustaining damage. This is particularly important in industries such as manufacturing, automotive, or aerospace where machinery operates under harsh conditions.

Assessing these factors — operating temperature range, IP ratings, and vibration/shock resistance — ensures that your motor will perform reliably under the specific environmental challenges it faces.

Quality and reliability

Quality and reliability are paramount when selecting a BLDC motor for your next project. To ensure you’re making the right decision.

- Manufacturer Reputation: Established manufacturers with a long history of producing reliable products often have rigorous quality control processes in place, ensuring that their offerings meet high standards.

- Warranty and Support: A robust warranty not only reflects confidence in product durability but also offers peace of mind to consumers. Reliable customer support can make a significant difference when issues arise, ensuring that users receive timely assistance and solutions.

- MTBF (Mean Time Between Failures): serves as an essential metric for assessing reliability. This statistic indicates the average time expected between failures for a particular product or system during operation. A higher MTBF rating indicates greater reliability.

Choosing a motor with proven reliability and support can save you from costly breakdowns and downtime in the long run.

Cost Considerations

When it comes to selecting a BLDC motor, it’s essential to the cost in both the short and long term.

Purchase Price is often the most immediate concern, as it can vary widely depending on the motor’s specifications, brand, and performance features. However, it matters to look beyond the upfront cost to ensure that the motor you choose provides long-term value.

Maintenance and Repair Costs should be factored into your decision. Some motors, while affordable at first, may require frequent maintenance, part replacements, or repairs, which can add to their total cost of ownership. Consider motors with longer warranties or lower maintenance requirements.

Return on Investment (ROI) needs to be considered when evaluating a motor’s cost. More efficient motors can reduce energy consumption, leading to lower operating costs, especially in power-hungry applications. In some industries, choosing a slightly more expensive but highly efficient motor can result in significant savings over its lifespan, ultimately providing better ROI.

To make a well-informed decision, it’s essential to balance the initial purchase price with long-term operational costs, ensuring the chosen motor is both cost-effective and capable of meeting your project’s requirements without sacrificing performance or durability.

Conclusion

Choosing the right BLDC motor for your project is a decision that requires careful consideration of specifications, application needs, control interfaces, environmental factors, and cost.

By thoroughly researching and understanding each of these elements, you can select a motor that not only meets your project’s demands but also performs reliably for years to come.

If you’re still uncertain about which motor is right for your needs, reach out to our team for expert advice.

We’ll help you navigate the selection process and find the perfect BLDC motor to power your project to success!