How Brushless DC Motors Are Shaping Industrial Automation

October 17, 2024

Table of contents

As industrial automation progresses, the need for efficiency, precision, and reliability has reached new heights. A crucial component driving many modern automated systems is the Brushless DC (BLDC) motor. With its exceptional performance, low maintenance requirements, and energy efficiency, the BLDC motor is transforming how industries operate, making it an essential part of today’s manufacturing landscape.

In this article, we’ll dive into how BLDC motors work, explore their ideal industrial automation applications, and discuss their significant benefits. Additionally, we’ll touch on the challenges associated with their adoption and the exciting future for BLDC motors in smart manufacturing.

What Are BLDC Motors and How Do They Work?

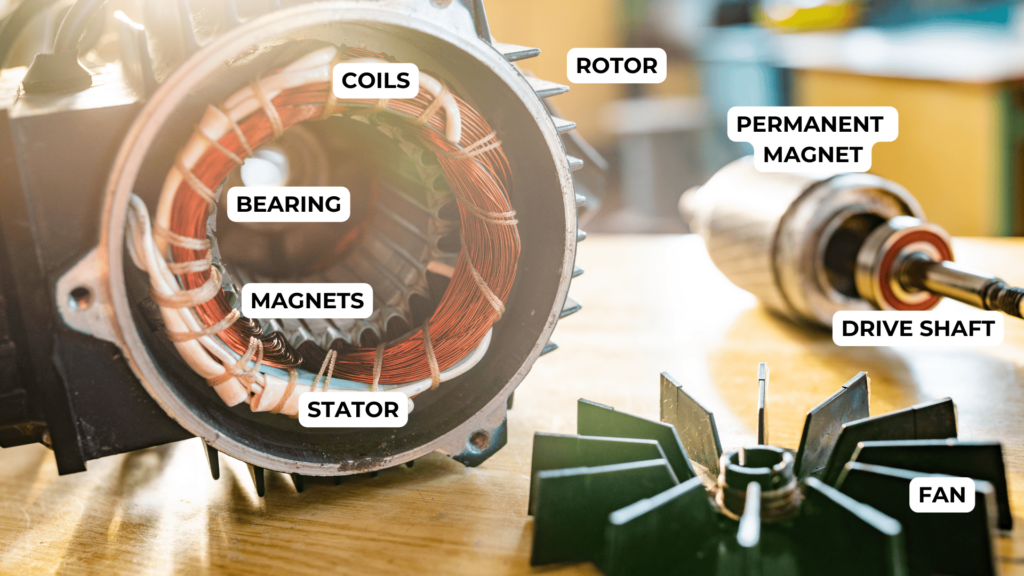

BLDC motors are distinct from traditional brushed motors, which use mechanical brushes to generate rotational movement. Instead, BLDC motors operate using a clever design that eliminates physical contact between components, minimizing wear and tear.

Here’s a breakdown of their inner workings:

- Structure: The rotor (the rotating part) features permanent magnets, while the stator (the stationary part) contains coils that produce an electromagnetic field.

- Electronic Control: An electronic controller manages the current flow through the coils, turning it on and off in precise sequences. This process creates a rotating magnetic field.

- Magnetic Interaction: The rotating magnetic field interacts with the rotor’s magnets, causing it to spin. This brushless design results in higher efficiency, a longer lifespan, and less maintenance compared to traditional motors.

Because of these features, BLDC motors produce less heat and energy loss, making them ideal for demanding industrial applications.

Why BLDC Motors are Ideal for Industrial Automation

In the realm of industrial automation, where precision and efficiency are critical, BLDC motors have become the preferred choice for many automated processes. Here are a few reasons why they stand out in this field:

Precision Control

BLDC motors excel in delivering smooth and accurate torque control. This precision is vital for high-stakes tasks like robotics and CNC (Computer Numerical Control) machining. The electronic control system allows for exact positioning, enabling industrial robots to execute complex tasks with impressive accuracy.

Energy Efficiency

In an industrial setting where downtime can be costly, BLDC motors shine with their reduced maintenance requirements. With fewer mechanical components subject to wear and tear, these motors can operate continuously with minimal interruptions. Their reliability makes them an excellent investment for applications like conveyor systems and material handling.

With these advantages, BLDC motors enhance productivity while lowering the total cost of ownership for industries embracing automation.

Durability and Low Maintenance

In an industrial setting where downtime can be costly, BLDC motors shine with their reduced maintenance requirements. With fewer mechanical components subject to wear and tear, these motors can operate continuously with minimal interruptions. Their reliability makes them an excellent investment for applications like conveyor systems and material handling.

With these advantages, BLDC motors enhance productivity while lowering the total cost of ownership for industries embracing automation.

Key Applications of BLDC Motors in Industrial Automation

Thanks to their adaptability, precision, and efficiency, BLDC motors are widely used across various automation systems. Here are some prominent applications where these motors significantly impact productivity:

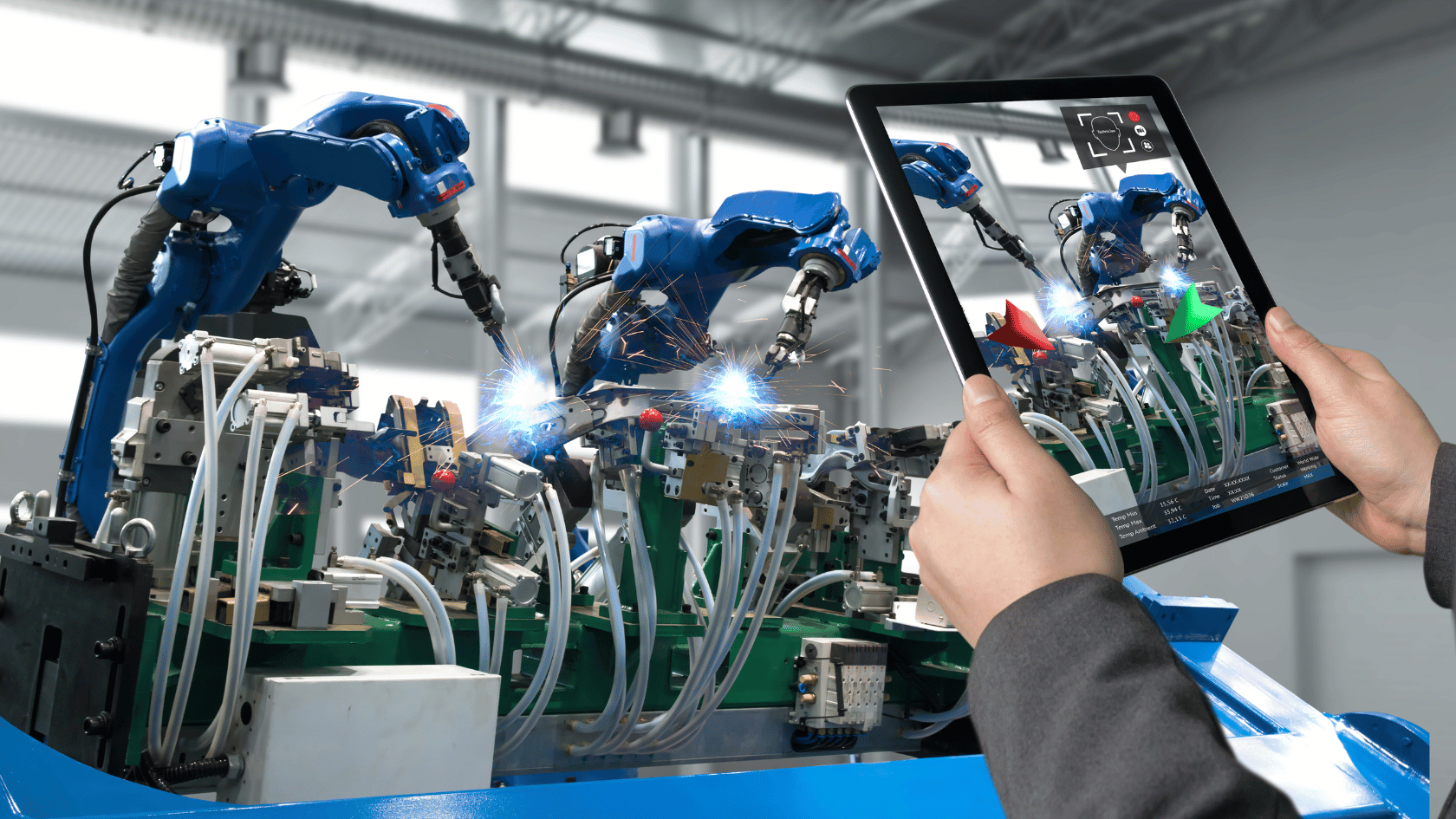

Robotic Arms

Robotic arms are crucial in manufacturing processes, from assembly to delicate component handling. BLDC motors power these arms, providing the precision control necessary for tasks like welding, painting, and packaging. Their high torque and fine motor control ensure smooth and accurate robot operations.

Conveyor Systems

In industrial environments that require efficient material movement, BLDC motors are integral to powering conveyor belts. These motors deliver consistent, reliable movement, facilitating the smooth transportation of goods across production lines. Their energy efficiency also helps reduce operational costs in environments reliant on continuous material handling.

CNC Machines

CNC machines are crucial in industries that require precision manufacturing, such as aerospace, automotive, and electronics. BLDC motors are commonly used in CNC systems to control the spindle and feed drives, providing the accurate and repeatable motion needed for precise cutting, drilling, and milling operations.

Servo Motors

BLDC motors are often used as servo motors in automation. A servo motor’s primary function is to provide accurate motion control in systems where precise positioning is essential, such as in robotic welding machines or automated inspection systems. The fast response time and precise control of BLDC motors make them ideal for these applications.

In all these applications, the versatility and reliability of BLDC motors significantly enhance the efficiency and accuracy of industrial automation systems, making them vital in modern manufacturing processes.

Benefits of Using BLDC Motors in Automation

Integrating BLDC motors into industrial automation offers numerous advantages that lead to improved operational efficiency and cost-effectiveness. Key benefits include:

Reduced Downtime

Thanks to their brushless design, BLDC motors experience less mechanical wear. This translates to longer service intervals and fewer breakdowns, which is crucial in high-stakes industrial settings where downtime can be extremely costly.

Minimal Maintenance

Unlike traditional motors that require regular maintenance for worn components, BLDC motors are low-maintenance. Their durability and extended lifespan mean industries can operate machinery for long periods without intervention, leading to lower operational costs over time.

Improved Energy Efficiency

In an environmentally conscious landscape, reducing energy consumption is critical. BLDC motors convert more electrical energy into mechanical power, with less heat loss, leading to lower power consumption. This efficiency not only benefits the environment but also reduces energy costs.

Operational Reliability

In environments demanding precision and continuous operation, BLDC motors provide the reliability needed to maintain high productivity levels. Their consistent performance ensures that automated systems run with minimal interruptions, contributing to overall operational success.

Challenges and Considerations When Using BLDC Motors

Despite their numerous advantages, there are a few challenges and considerations to keep in mind when adopting BLDC motors in industrial automation:

Higher Initial Cost

BLDC motors typically come with a higher upfront price tag due to the complexity of their electronic control systems. This can be a barrier for some companies considering the technology. However, the long-term benefits of efficiency and reduced maintenance often outweigh the initial investment.

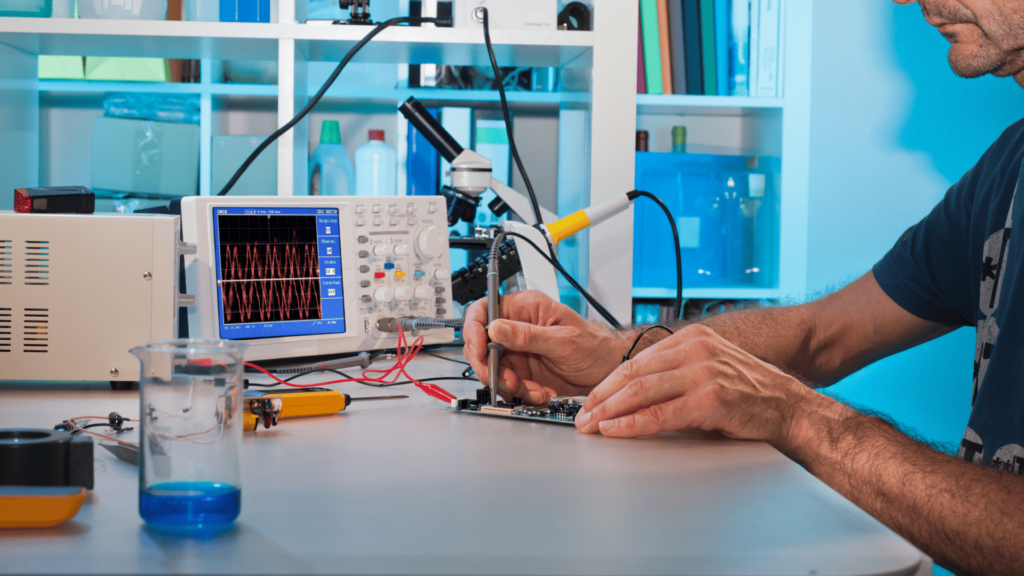

Complexity of Integration

Integrating BLDC motors into existing systems may require specialized expertise, particularly when configuring the electronic controllers. Proper calibration is essential to ensure optimal performance, which might necessitate additional skills or software.

Sensitivity of Controllers

The electronic control systems driving BLDC motors can be sensitive to electrical noise and fluctuations. Proper shielding and installation are crucial to prevent interference and ensure reliable performance.

Future Trends: The Role of BLDC Motors in Industry 4.0

As the industry moves toward Industry 4.0 and smart factories become a reality, the role of BLDC motors in industrial automation is set to expand further. In IoT-enabled systems, BLDC motors can be integrated with sensors and data analytics, facilitating predictive maintenance and real-time monitoring. This capability allows factories to optimize their operations and respond proactively to potential issues.

Moreover, as industries strive to meet sustainability goals, the energy efficiency of BLDC motors will become increasingly valuable. Their ability to reduce energy consumption will solidify their position as a critical technology in the automation landscape moving forward.

Conclusion

BLDC motors are revolutionizing industrial automation by providing the precision, efficiency, and reliability essential for modern manufacturing processes. From powering robotic arms and CNC machines to driving conveyor systems and servo motors, these motors enable industries to boost productivity while minimizing costs and energy consumption.

For businesses aiming to stay competitive in an increasingly automated and sustainable future, adopting BLDC motors is not just beneficial but essential. By leveraging these advanced motors, companies can unlock new levels of efficiency and innovation, positioning themselves for success in the dynamic world of Industry 4.0.