The Role of BLDC Motors in Consumer Electronics

September 5, 2024

Table of contents

As consumer electronics continue to evolve, Brushless DC (BLDC) motors have become a key technology, enhancing performance, efficiency, and user experience. Known for their reliability and energy-saving benefits, these motors are now key components in everything from smartphones and laptops to home appliances and electric vehicles. BLDC motors are reshaping the way we use technology in everyday life.

In this article, we’ll explore how BLDC motors impact consumer electronics and share practical technical details that will resonate with industrial engineers and product managers alike.

1. Understanding BLDC Motors: Key Technical Insights

The Basics of BLDC Motor Operation

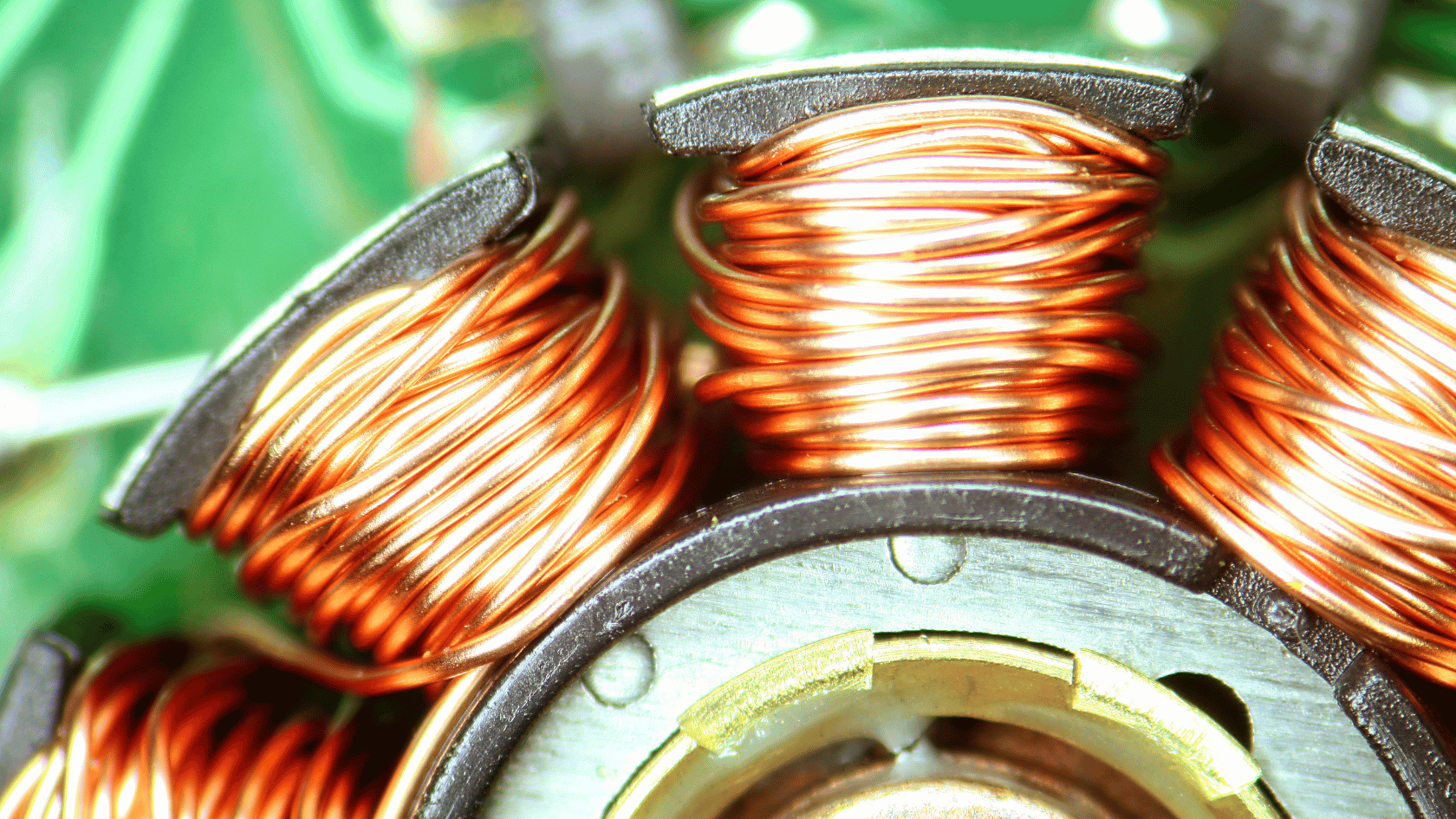

At the core of a BLDC motor is the absence of mechanical brushes that are typically used in conventional DC motors. Instead of brushes, BLDC motors utilize an electronic controller to manage the current flowing through the motor’s windings.

This control generates a rotating magnetic field that interacts with the rotor’s permanent magnets, generating torque and setting the rotor in motion.

- Stator: The stator, made from laminated steel sheets, contains copper windings that generate a rotating magnetic field when electric current passes through them. The design of the stator, including the number of slots and the winding configuration, is critical in determining the motor’s performance characteristics, such as speed and torque.

- Rotor: The rotor is fitted with permanent magnets, often made of materials like neodymium. These magnets generate a strong magnetic field, enabling the motor to deliver high torque even at low speeds, which is crucial for precise control in consumer electronics.

- Electronic Controller: The controller is a sophisticated device that uses algorithms to switch the current in the windings, ensuring the magnetic fields are correctly aligned to produce smooth and efficient rotation. Advanced controllers can include features like Field-Oriented Control (FOC), which improves torque response and efficiency, making BLDC motors especially suited for applications requiring precise control.

Advantages of BLDC Motors in Consumer Electronics

Efficiency and Energy Savings

One of the primary advantages of BLDC motors in consumer electronics is their superior energy efficiency. BLDC motors can achieve efficiencies greater than 85%, compared to 75% in traditional brushed motors. This efficiency is crucial in battery-powered devices like smartphones, tablets, and wearable electronics, where extended battery life is a key selling point. For instance, the implementation of BLDC motors in cooling fans of laptops reduces power consumption, allowing for longer use between charges.

Compactness and Power Density

BLDC motors are known for their high power density, meaning they can deliver significant power output in a compact form factor. This is particularly important in modern consumer electronics, where space is at a premium.

In smart home appliances, such as robotic vacuum cleaners, BLDC motors provide the necessary power for robust operation while maintaining a compact and lightweight design, enhancing user convenience.

Low Noise and Vibration

The absence of brushes in BLDC motors eliminates the friction that typically generates noise and vibration in traditional motors. This makes BLDC motors ideal for audio and video equipment where low noise is critical for maintaining sound and picture quality.

For example, in high-end audio speakers, BLDC motors drive cooling fans with minimal noise, ensuring that audio playback remains clear and undistorted.

2. BLDC Motors in Specific Consumer Electronics Applications

Smartphones and Portable Devices

In smartphones and other portable gadgets, BLDC motors are utilized in vibration motors to offer haptic feedback. These motors provide accurate, tactile responses that improve user engagement with touchscreens.

Modern BLDC motors in smartphones enable customizable vibration patterns, enabling manufacturers to distinguish their devices by offering distinctive haptic feedback encounters.

Home Appliances

Modern home appliances, such as washing machines and refrigerators, benefit significantly from BLDC motors. In washing machines, for instance, BLDC motors provide direct drive systems that eliminate the need for belts and pulleys, reducing mechanical losses and improving energy efficiency. The result is a quieter, more durable appliance with better washing performance.

Similarly, in refrigerators, BLDC motors drive compressors with greater efficiency, leading to lower energy consumption and reduced operating costs for consumers.

Electric Vehicles and Personal Transport Devices

BLDC motors are also revolutionizing the market for electric vehicles (EVs) and personal transport devices like electric scooters and hoverboards. Thanks to their high torque and efficiency, these motors are perfect for applications where battery life and performance are key.

In EVs, for instance, BLDC motors deliver smooth, responsive acceleration and help extend driving ranges by maximizing energy efficiency.

Gaming and Virtual Reality (VR) Devices

In the gaming industry, BLDC motors are used in force-feedback controllers and VR devices to create immersive experiences.

These motors provide precise control over the intensity and direction of force feedback, allowing gamers to feel every bump, hit, or explosion in the virtual world. This kind of immersive experience is crucial for today’s gaming systems, where realism and player engagement are essential.

Power Tools

BLDC motors have revolutionized the power tools industry with their high torque and steady speed control in a compact design. Cordless drills, for instance, now feature BLDC motors that provide superior torque output while extending battery life due to their energy-efficient design.

Additionally, these motors generate less heat, meaning they can operate for longer periods without overheating, reducing wear and tear on the tool and boosting its overall durability.

Drones and UAVs

BLDC motors are essential for today’s drones and unmanned aerial vehicles (UAVs). They provide the precise and responsive control needed for stable flight and quick maneuvers. The high efficiency of BLDC motors allows for extended flight times, while their reliability ensures consistent performance in demanding conditions, whether in recreational drones or commercial UAVs used for surveillance, mapping, or delivery services.

3. Technical Challenges and Solutions in Implementing BLDC Motors

Complexity of Motor Control Systems

One of the main challenges in implementing BLDC motors in consumer electronics is the complexity of the motor control systems. Designing an efficient electronic controller that can handle real-time adjustments based on sensor feedback requires sophisticated algorithms and precise engineering.

Field-Oriented Control (FOC), for example, is an advanced technique used in controllers to optimize the performance of BLDC motors by precisely controlling the current flow, ensuring maximum torque and efficiency at varying speeds.

Heat Management

Heat dissipation is a critical factor in the performance of BLDC motors, especially in compact electronic devices where space for cooling is limited. Engineers need to incorporate effective heat management solutions, like built-in heat sinks and active cooling systems. These measures keep the motors running at the right temperatures, ensuring they perform reliably and last longer.

Cost Considerations

While BLDC motors offer numerous advantages, they can be more expensive to produce than traditional motors due to the complexity of their electronic controllers and the use of rare-earth materials in their magnets.

However, advancements in manufacturing techniques and the development of cost-effective alternatives to rare-earth magnets are helping to reduce these costs, making BLDC motors more accessible for a wider range of consumer electronics.

4. Future Trends in BLDC Motors for Consumer Electronics

Integration with IoT and Smart Technologies

BLDC motors are set to take consumer electronics to the next level by integrating with Internet of Things (IoT) technologies.

Smart home devices, for example, can use BLDC motors to adjust their operation based on real-time data from connected sensors, optimizing performance and energy use. This push towards smart automation is increasing the demand for BLDC motors that are not just efficient and reliable but also seamlessly compatible with IoT systems.

Advancements in Materials and Manufacturing

Ongoing research in materials science is leading to the development of new magnetic materials that could replace rare-earth elements in BLDC motors, reducing costs and dependency on specific resources.

Additionally, advancements in additive manufacturing (3D printing) are enabling the production of more complex motor designs, which can further enhance the performance and efficiency of BLDC motors in consumer electronics.

Customization and Personalization

As consumer demand for personalized products grows, BLDC motors are being designed with greater flexibility in mind.

Manufacturers are offering customizable motor parameters that allow product designers to tailor motor performance to the specific needs of their devices, whether it’s adjusting speed, torque, or noise levels. This customization capability is becoming increasingly important in the competitive consumer electronics market, where differentiation is key.

Conclusion

Brushless DC motors are becoming increasingly important in consumer electronics, offering efficiency, accuracy, and dependability. From smartphones to electric vehicles, these motors are central to the devices we use every day.

As electronic products evolve to become smarter, more efficient, and more powerful, BLDC motors continue to play a key role in pushing innovation forward. For engineers and product developers, understanding the intricacies of BLDC motors and keeping up with new developments will be essential in designing the future of consumer electronics.