How BLDC Motor Technology is Transforming Drones and Robotics

September 9, 2024

Table of contents

The evolution of BLDC motor technology has dramatically transformed the fields of drones and robotics, pushing technological boundaries in numerous industries.

This advanced motor technology offers enhanced efficiency, durability, and precision control, making it the top choice for engineers designing high-performance systems. Unlike traditional brushed motors, BLDC motors provide superior performance, leading to longer lifespans and reduced maintenance.

In this article, we explore the technical benefits of BLDC motor technology and its significant role in revolutionizing drones and robotics.

The Fundamentals of BLDC Motor Technology in Drones and Robotics

What is BLDC Motor Technology?

BLDC motor technology operates without mechanical brushes, a key differentiator from traditional brushed motors. In brushed motors, brushes physically contact the commutator to switch the current, but BLDC motors achieve this electronically.

Controllers switch the current flow, creating a rotating magnetic field that interacts with the rotor’s permanent magnets, producing smooth rotation.

Key Components of BLDC Motor Technology

BLDC motor technology consists of three primary components:

- Stator: Made from laminated steel sheets and copper windings, the stator generates a magnetic field when current flows through it. The number of poles and winding configurations directly impact torque and speed, making stator design critical for performance.

- Rotor: The rotor includes permanent magnets, often made from rare-earth materials such as neodymium. The number of poles on the rotor affects the motor’s torque and smoothness, which is crucial for applications requiring precision.

- Electronic Controller: The controller regulates the current in the stator windings, using feedback from sensors like Hall effect sensors or back EMF. This ensures precise speed and torque control, necessary for stabilizing drones and robotic movements.

How BLDC Motor Technology Enhances Drone Performance

Improved Efficiency and Power Density

BLDC motor technology is known for its efficiency, often exceeding 85%, compared to 75% for traditional brushed motors. This efficiency is vital for drones, as it directly impacts flight time.

For instance, drones powered by BLDC motor technology can fly longer and carry heavier payloads, such as high-resolution cameras or LiDAR systems, without sacrificing performance.

Precision Control for Stability

Drones require stable and precise control, and BLDC motor technology delivers by reducing mechanical noise and providing finer speed control. This smooth operation is essential for tasks like aerial photography, where stable positioning is key to capturing high-quality footage.

Reduced Maintenance and Extended Lifespan

The absence of brushes in BLDC motor technology eliminates friction-based wear and tear, drastically reducing maintenance needs.

Unlike brushed motors that require frequent brush replacements, BLDC motors have a longer operational lifespan and are more reliable over extended periods. This reliability is a key factor in applications where drones are used in remote or hard-to-access locations.

The Impact of BLDC Motor Technology on Robotics

High Torque at Low Speeds

In robotics, the ability to generate high torque at low speeds is essential for tasks that require precision and control, such as robotic arms and industrial robots.

BLDC motors excel in this area, providing the necessary torque without sacrificing efficiency. This makes them ideal for robotics applications that demand both power and accuracy.

Compact Design and Lightweight Advantage

The compact and lightweight nature of BLDC motors makes it a perfect fit for robotics, where space and weight constraints are critical considerations. In applications like exoskeletons designed for mobility assistance, these motors provide ample power without adding unnecessary bulk.

Superior Heat Dissipation

Continuous operation in robotics often presents heat management challenges. BLDC motors mitigate these issues by eliminating the friction caused by brushes and incorporating advanced designs that dissipate heat more effectively, ensuring consistent performance over long periods.

Applications of BLDC Motor Technology in Drones and Robotics

Aerial Drones

BLDC motors are the driving force behind the rapid development of aerial drones used in various industries, including agriculture, surveillance, delivery, and environmental monitoring. Their ability to provide high efficiency, precise control, and reliability makes them the motor of choice for drone manufacturers.

Robotic Arms and Manipulators

In industrial robotics, BLDC motors power robotic arms and manipulators used for tasks such as assembly, welding, and material handling. The high torque, precision control, and compact design of BLDC motors enable these robots to perform complex and repetitive tasks with high accuracy and reliability.

Autonomous Vehicles (AVs)

Autonomous vehicles, including self-driving cars and unmanned ground vehicles (UGVs), rely on BLDC motors for propulsion and steering. The motors’ ability to deliver high torque and precise control is crucial for the safe and efficient operation of these vehicles in various environments.

Medical Robotics

In medical devices such as surgical robots and prosthetic limbs, BLDC motors play a crucial role. The precision and reliability of these motors are critical in life-saving applications like robotic-assisted surgery, where they enable minimally invasive procedures with enhanced accuracy.

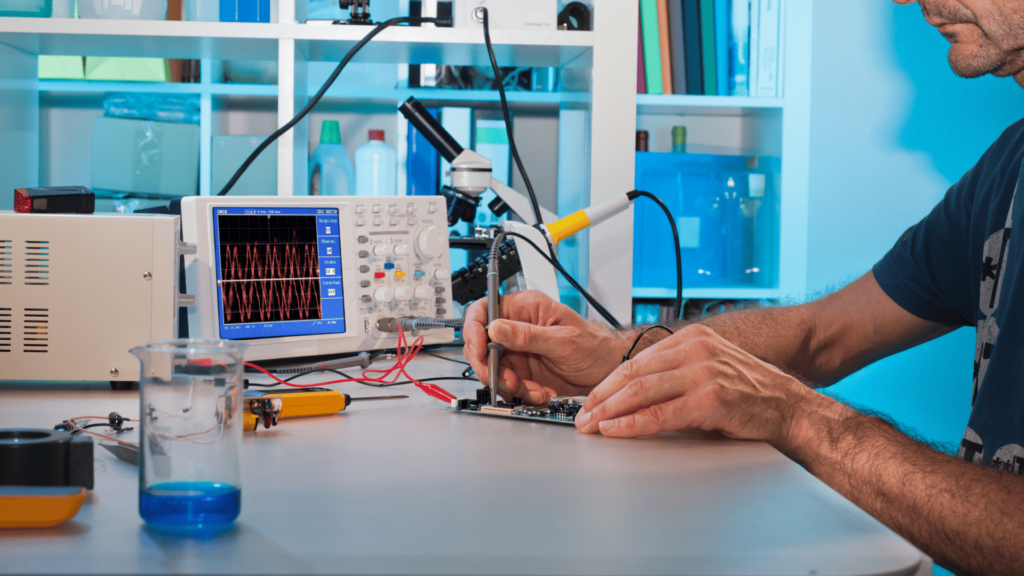

Overcoming Challenges in BLDC Motor Technology Implementation

Complexity of Motor Control

One of the challenges in implementing BLDC motors is the complexity of the electronic control required to manage the motor’s operation. Engineers must design and program sophisticated controllers that can handle the real-time switching of currents in the motor windings while maintaining precise control over speed and torque.

Cost Considerations

While BLDC motors offer numerous advantages, they can be more expensive than brushed motors due to the complexity of the electronic controllers and the use of permanent magnets. However, the long-term benefits, including reduced maintenance costs and longer lifespan, often justify the initial investment.

Availability of Magnet Materials

The availability and cost of rare-earth materials used in permanent magnets, such as neodymium, can impact the production and pricing of BLDC motors. Engineers and manufacturers must consider these factors when designing and sourcing BLDC motors for specific applications.

Conclusion

BLDC motors have become a foundational element in drone and robotics innovation. Their unmatched efficiency, precise control, and extended lifespan make them essential for applications ranging from aerial drones to sophisticated robotics.

As these fields progress, this motor technology will continue to fuel advancements, opening the door to new possibilities. For engineers and manufacturers, understanding its complexities and addressing implementation challenges will be crucial to harnessing its full potential.